The drum-shaped gear coupling is to make the external teeth into a spherical surface, the center of the spherical surface is on the gear axis, and the gap on the ulnar side is larger than that of the ordinary gear. The drum-shaped gear coupling can allow a larger angular displacement (relative to the straight gear coupling), which can improve the contact conditions of the teeth, increase the torque capacity, and extend the service life.

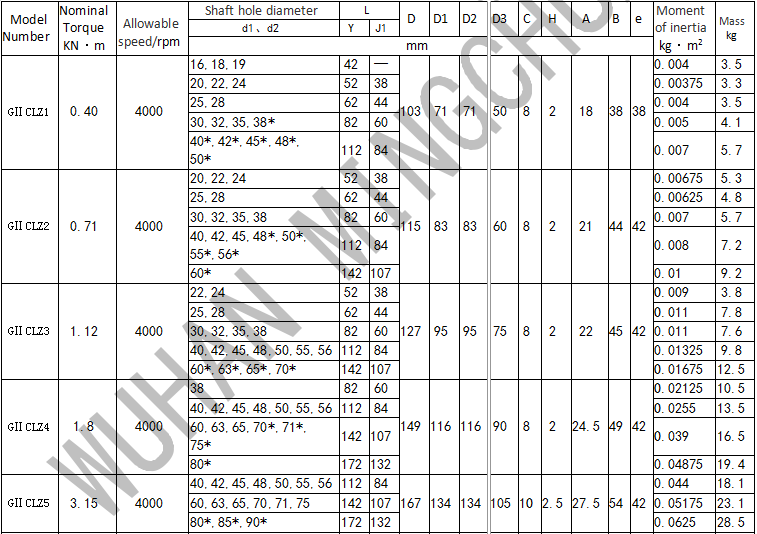

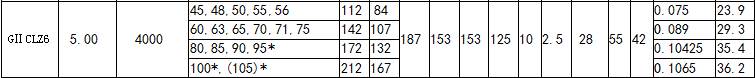

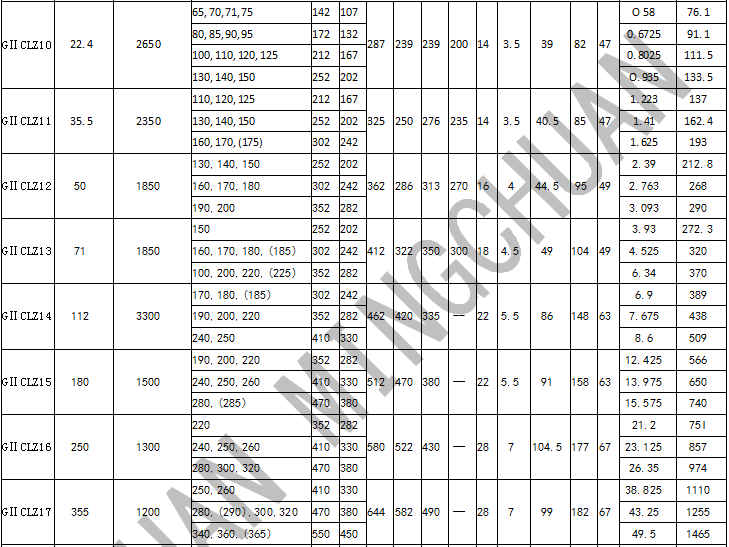

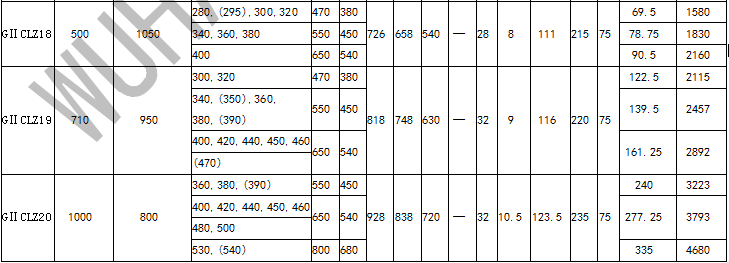

GIICLZ type intermediate shaft (narrow type) drum-shaped gear coupling has small tooth spacing, allows small relative radial displacement, compact structure, and small rotational inertia. It is suitable for nominal torque 400~4500000N·m. Spool drive.