Safety coupling (also called torque limiter, torque limiter, safety clutch) is a component that connects the active machine and the working machine. Its main function is overload protection. The torque limiter is required when overload or mechanical failure When the torque exceeds the set value, it limits the torsional force transmitted by the transmission system in the form of a slip, and restores the connection after the overload condition disappears. This prevents mechanical damage and avoids costly downtime losses.

Only using a mechanical torque limiter can quickly cut off the connection between the motor and the spindle, thereby eliminating the destructive effect of inertial force. For ordinary machinery, including the transmission of the conveyor, office machinery and various instruments, mechanical torque limiters such as shear pin safety couplings and friction clutches can provide good safety protection. However, they still cannot meet the requirements of high-performance equipment such as machine tools. One problem is that ordinary clutches and couplings transmit torque and deviation to the protected shaft. In special applications, there are some other problems. However, the safety coupling is a new type of mechanical torque limiter, which can overcome the above-mentioned traditional problems. Safety couplings are best suited to ensure that high-speed, high-precision drives are protected from overload damage. This coupling is not a refinement of an ordinary torque limiter, but a product specially designed in cooperation with machine tool manufacturers to meet certain specific requirements.

All safety couplings have the following characteristics:

●There is no gap in the connection of keyless shaft sleeve

●High torsional rigidity, low inertia moment, small size, separation torque can be adjusted arbitrarily

●The original position can be maintained after reconnecting the platform

●Alarm when overload,

●Two types of automatic rejoining and non-automatic rejoining are available, with heat resistance (above 260℃).

In addition, some types of safety couplings also compensate for the axial displacement, lateral displacement and angular displacement of the shaft. On the pulleys and sprockets, some also have integral ball bearings. These characteristics make the safety coupling not only suitable for machine tool transmissions, but also suitable for high-performance assembly lines, printing machinery, packaging machinery, etc.

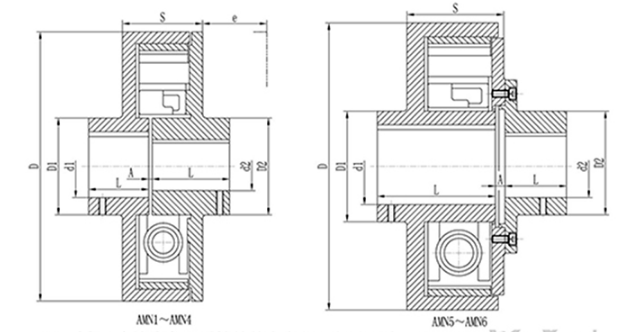

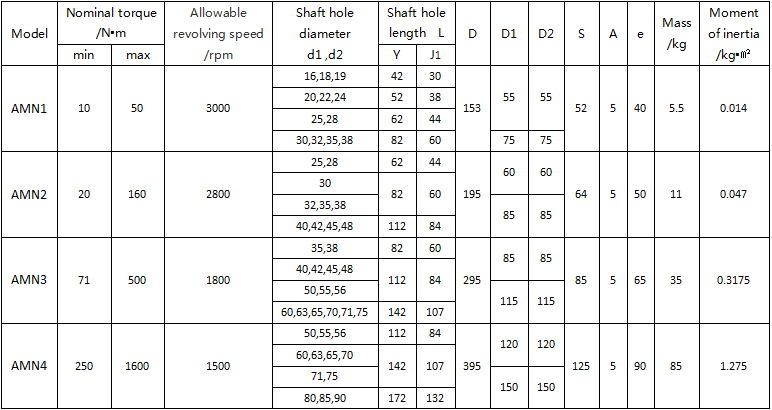

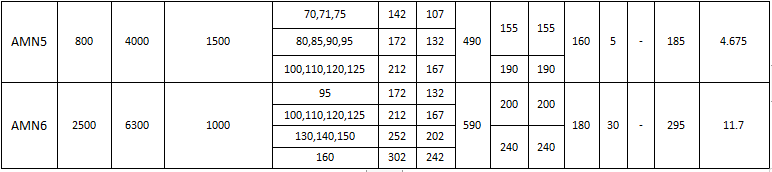

Internal tension type friction safety coupling is a structural type of friction type safety coupling. Two cylindrical coil springs are used to press the arc-shaped friction plates through the intermediate ring to generate friction between the friction plates. The size determines the sliding torque of the coupling. Adjust the sliding torque of the coupling by replacing the spring. When the transmitted torque exceeds the sliding torque of Lingsi coupling, the coupling slips between the main and driven sides; when the transmitted torque is lower than the sliding torque, no relative sliding on both sides of the coupling will automatically recover normal work.

Normal operation within the range of use, generally no need to replace parts, under the premise of the correct use of the AMN internal tension friction safety coupling, it can effectively partially reduce the impact load of the shafting drive at the start, and accelerate the machine Start, at the same time can prevent the motor from burning due to overload. It can be used in working conditions requiring overload safety protection to avoid the destruction of key parts.

The characteristics and uses of safety couplings are as follows:

1. Wide range of torque control and high control accuracy. Torque is proportional to the exciting current in a fairly wide range, which can perfect and simplify the control of transmitting torque, and can be used as a linear adjustment element.

2. With constant torque, the torque only depends on the magnitude of the exciting current, and has nothing to do with the relative torque of the master and slave sides. It has constant torque and the static torque is the same as the dynamic torque.

3. It can transmit a certain torque without being related to slip, without impact, vibration, noise, and smooth operation. It can be used in occasions with high working frequency.

4. Less power consumption and less control power. The residual torque when the excitation current is disconnected is small, the disconnection performance is good, there is no heat phenomenon when idling, the stability of the torque is good, and it can be used for precise control.

5. The structure is simple, the volume is small, the mass is small, the magnetic powder does not need oil to dry, easy to maintain, the magnetic powder has oxidation resistance, good heat resistance, long life and high reliability. The driven part is fixed, and the torque becomes the braking torque for the rotating part, which can become a magnetic powder coupling and can also become a magnetic powder load.